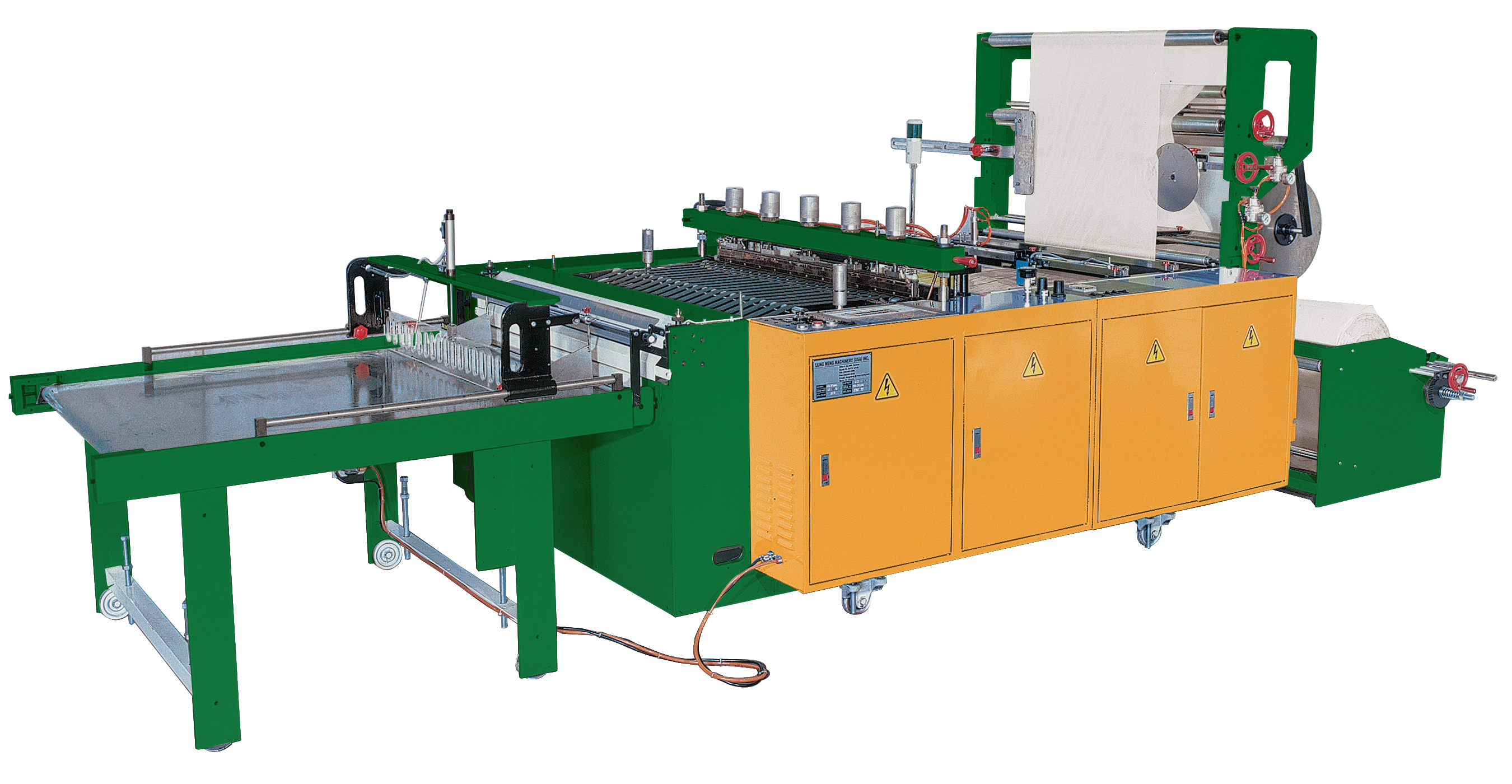

ASTP800C~ASTP1200C

UNIVERSAL BAG MAKING MACHINE

- Designed for side seal,bottom seal and double bottom seal bags, which takes less than 1/2 hour for the change over.

- Servo driven control system , high speed production output at 200bags/min.

- Abnormal indicator to protect the machine and easy troubleshooting.

- Advanced microprocessor motion control for quick length change and photo registrastion.

- Punching Device.

- Seat Pad Heating Device.

- Dot Seal Device.

| Model | ASTP-800C | ASTP-1000C | ASTP-1200C | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Sealing Type | Side Seal | Bottom Seal | Double Seal | Side Seal | Bottom Seal | Double Seal | Side Seal | Bottom Seal | Double Seal |

| Cutting Width(mm) | 60-770 | 60-770 | 80-770 | 60-770 | 60-1020 | 80-1020 | 60-770 | 60-1220 | 80-1220 |

| Cutting Length(mm) | 60-770 | 60-770 | 80-770 | 60-1020 | 80-800 | 80-800 | 60-1220 | 80-800 | 80-800 |

| Machine Speed(Cycle/Min) | 30-200 | 30-160 | 30-160 | 30-200 | 30-160 | 30-160 | 30-200 | 30-160 | 30-160 |

| Thickness of Film (mm) | Side Seal | Bottom Seal | Double Seal | Side Seal | Bottom Seal | Double Seal | Side Seal | Bottom Seal | Double Seal |

| LDPE Min. Thickness | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 |

| HDPE Min. Thickness | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| LDPE Total Max. Thickness | 0.2 | 0.3 | 0.3 | 0.2 | 0.3 | 0.3 | 0.2 | 0.3 | 0.3 |

| HDPE Total Max. Thickness | 0.07 | 0.2 | 0.07 | 0.07 | 0.2 | 0.07 | 0.07 | 0.2 | 0.07 |

| Tolerance(mm) | ±1 | ±1.5 | ±1.5 | ||||||

| Power Required(kw) | 9KW | 11KW | 12KW | ||||||

| N.W.(KGS) | 1600KG | 1800KG | 2000KW | ||||||

| Machine Size(mm) | 4800x1580x1881 | 4800x1830x1881 | 4800x2030x1881 | ||||||

- Specifications subject to change without notice.