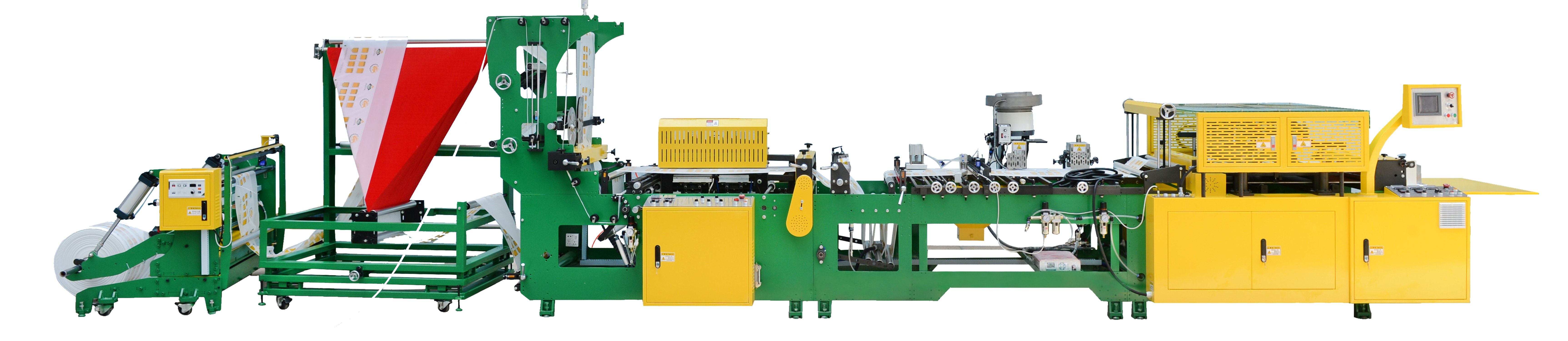

B700-ZPB

Zipper Bag Machine

- Unwind Unit: Powder break tension control with EPC.

- Zipper Attachment Device: Utilizes continuous sealing units and cooling system to feed and attach zipper profiles.

- Inverter Controller: For smoothly in-feed control.

- Servo Motor: Servo Driven with PLC control for accuracy and reliability.

- Sealing Blades: Can be customized in accordance with the profile style in use.

- Ultrasonic flattening: Device to reinforce the seal.

- Photocell registration: Accurate and reliable positioning of printing registration.

- HMI touch panel: Simple to operate LCD touch panel that monitors production and makes quick adjustments.

- Automatic Alarm: Visual alarm that sounds and stops machine when detecting a malfunction, such as profile jamming or running out of material.

- Triangle Folding Device,

- Continuous Perforating Device.

- Spool type Automatic Profile Unwind Unit.

- Various styles of punching units (Butterfly, Calendar, Kidney, Notch, Round and more)

| Model | B450-ZPB | B700-ZPB | B850-ZPB | B1050 |

| Output (Pcs/Min) | 20-120 | 20-120 | 20-80 | 20-60 |

| Bag Width (mm) | 50-1000 | 50-1000 | 50-1000 | 50-1000 |

| Bag Length (mm) | 50-450 | 50-700 | 50-850 | 50-1050 |

| Converting Thickness (mm) | 0.016-0.3 | |||

| Feed Roller Width (mm) | 500 | 700 | 900 | 1100 |

| Main Electrical Machinery (kw) | 1.5 | 1.5 | 2 | 2 |

| Servo Electrical Machinery (kw) | 1.5 | 1.5 | 2 | 2 |

| Total Outpot (kw) | 6 | 7 | 8 | 10 |

| Overall Dimensions (mm) | 8000*1050*1850 | 8000*1300*1850 | 8000*1500*1850 | 8000*1700*1850 |

| Machine Weight (kg) | 2000 | 2500 | 3000 | 3500 |

- Specifications subject to change without notice.