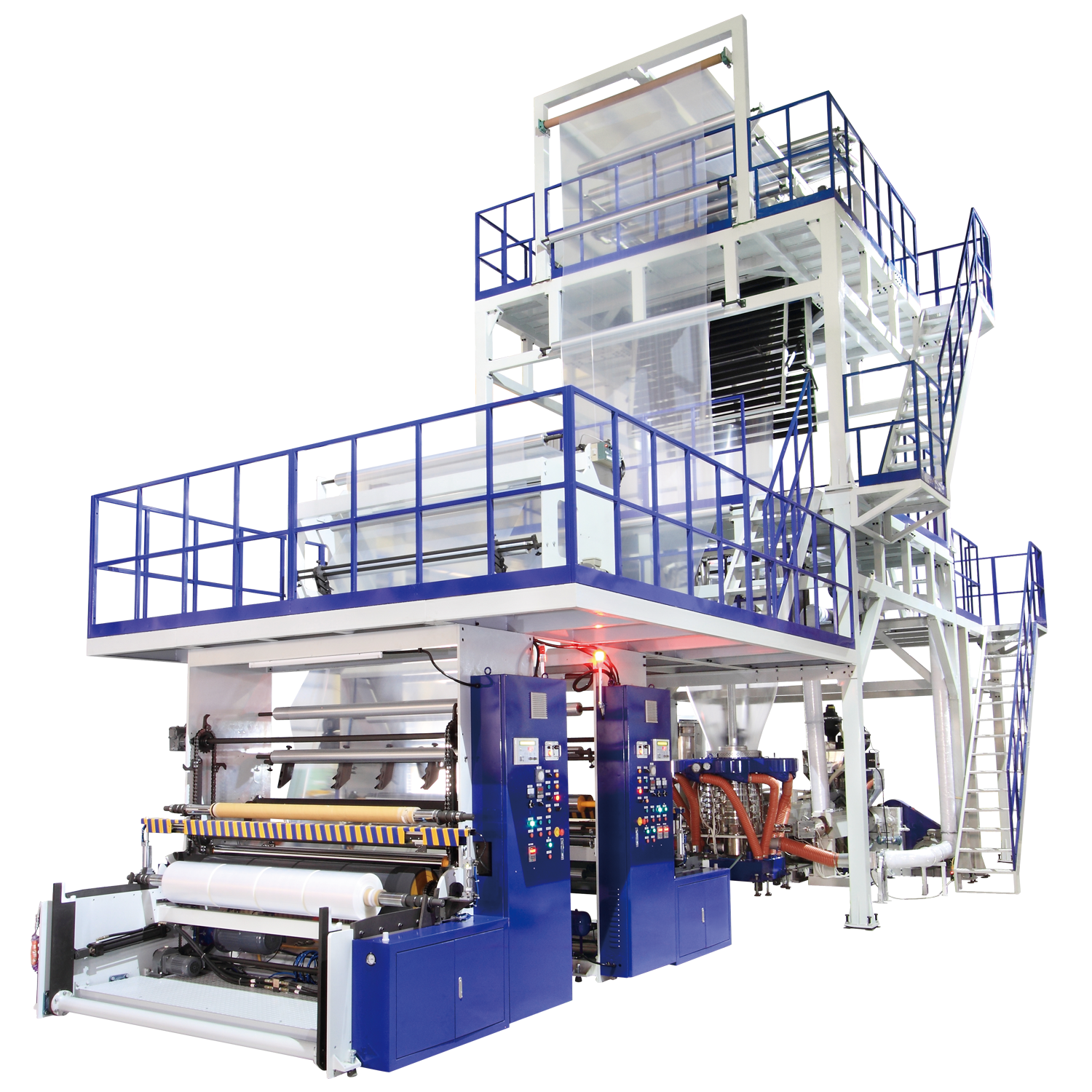

CE-55-90-55-TT

A/B/C THREE LAYER BLOWN FILM MACHINE

- Horizontal Oscillating Haul off with PLC control.

- Teflon Rolls, Remote control motorized open/close, up/down Bubble Cage.

- Bimetallic barrel with replaceable groove section and cooling jacket.

- Melt pressure/temperature probes and display Include rapture disk.

- 450mm A/B/C three layer IBC Ready Die and Air Ring.

- Automatic Magazine winding shaft loading, Back-to-Back Surface Winder, with loadcell and PLC control and slitting and edge open knives.

- IBC & automatic width control and Blower.

- Chiller and Chill Air Box for IBC and Air Ring.

- Gravimetric blender dosing system.

- Yield control management system.

- Real Time Thickness measurement system.

- BF-A A-Frame thickness measurement system.

- BF-E edge thickness measurement system.

- BF-S scanner thickness measurement system.

- Automatic Profile thickness control Air Ring.

- PIB Gear Pumps.

| Model | Suitable Material | A/B/C Screw Dia. | Max. Film Width | Max. Output | Screw L/D Ratio | Main Motor (w/inverter) |

|---|---|---|---|---|---|---|

| CE55/65/55TT | HDPE/LDPE/LLDPE/MLLDPE | A: Ø55/ B: Ø65/ C: Ø55 | 1600mm | 300Kg/Hr | A: 30:1/ B: 30:1/ C: 30:1 | A: 40HP/ B: 60HP/ C: 40HP |

| CE55/90/55TT | HDPE/LDPE/LLDPE/MLLDPE | A: Ø55/ B: Ø90/ C: Ø55 | 2000mm | 400Kg/Hr | A: 30:1/ B: 30:1/ C: 30:1 | A: 40HP/ B: 150HP/ C: 40HP |

| CE65/90/65TT | HDPE/LDPE/LLDPE/MLLDPE | A: Ø65/ B: Ø90/ C: Ø65 | 3000mm | 500Kg/Hr | A: 30:1/ B: 30:1/ C: 30:1 | A: 75HP/ B: 150HP/ C:75HP |

- Specifications subject to change without notice.